Hones for through bores

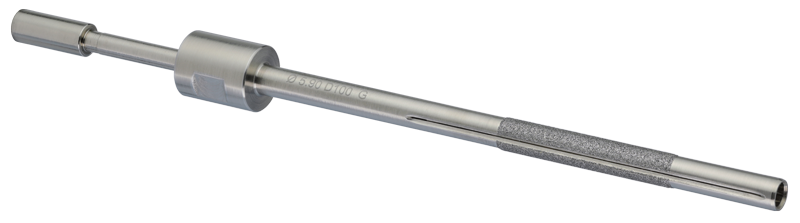

Galvanic honing tools

The standard 504, 504L, 400 and 400 L galvanic hone types have a body with slots which can be expanded micron by micron and are designed for use with through bores.

Their abrasive coatings form a single coating of diamond or CBN.

These honing tools are generally used for roughing operations with a higher stock removal rate.

These honing tools also have the ability of being able to machine bores with grooves or keyways.

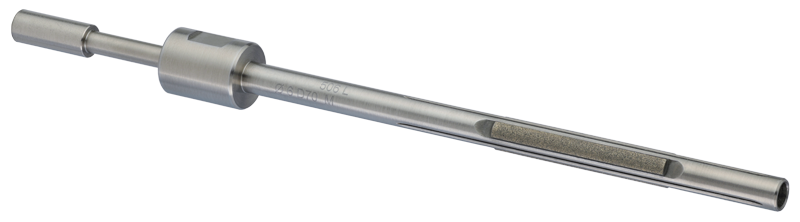

Metal bond honing tools

The 506, 506L, 401 and 402 metal type hones have a body with slots which can be expanded micron by micron and are designed for use with through bores.

Their abrasive coatings consist of metal inserts containing diamond, CBN or both mixed in multi-layers.

These honing tools have a lower cutting power than the galvanic type and are mainly used for finishing or superfinishing but have a longer lifespan. These honing tools are also very popular for honing soft, non-ferrous materials.

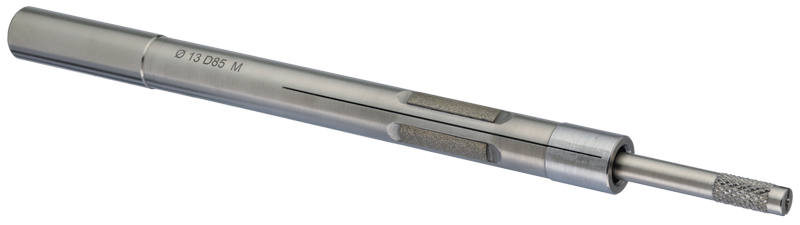

Resin bonded tools

The hand rotors 101 and 102 are resin type and the hones 201 and 202 are metal bond types.

Their expansion is done with a knurled screw placed at the front of the honing head and are very appreciated for the correction of bores in plastic injection moulds.