Hand honing apparatus

On an existing processing machine – like a milling machine or a lathe – Mu-Tools offers manual honing devices that allow the machine to be converted into a low-cost honing machine.

Thanks to the expansion system of these devices, geometry and repeatability within the micron can be achieved, even for people who have no experience in honing.

Each division of the micrometric drum represents 1 micron of expansion of the honing tool and is easily visible during the entire honing operation.

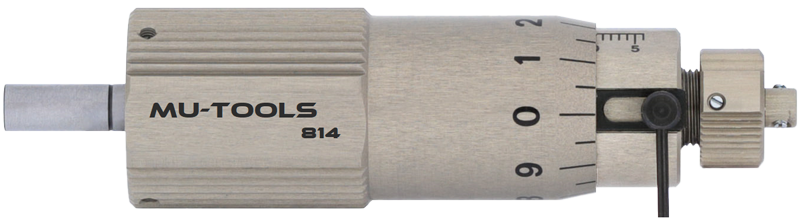

Mu-Tools 814

Hand honing apparatus type 814 for diameters of 0.6 to 1.5 mm

In the 814 honing apparatus, a friction-clutch system is incorporated to protect the small diameter honing tools.

Technical data

- For honing tools Ø 0.6 – 1.5 mm

- With built-in friction-clutch

- Length: 80 mm without clamping shank and without tools

- Clamping shank Ø 6 mm

- Ready for use immediately and everywhere

- Ideal for individual and Small production Runs

- Minimum changeover time

- The sensitive micrometric expansion allows controlled machining at every stage. During the entire processing time, the respective material removal can be read off on the scale drum.

- Maintenance-free

- With micrometric expansion

- Expansion of the honing tools during the machining via micrometre screw

- Repeat accuracy within 0.001 mm, reduces control measurements to a minimum

Honing

- An even expansion, and parallel bores achieved over the entire circumference up to 0.1 mm

- Available from Ø 0,6 mm

- Maximum honing length: 12.5 mm / 10.5 mm for Ø 0.6 and 0.7 mm

- Grit size galvanic tools : D 35, D 30 and D 15

Mu-Tools 220

Hand honing apparatus type 220 for diameters from 1.5 to 21 mm

A special adapter with a friction-clutch can also be used for manual honing when using the 220 unit, this is to protect small diameter honing tools.

Technical data

- For honing tools Ø 1.5 to 20 mm

- Turns your drilling, turning or milling machine into a precision honing machine

- Very handy design and very easy handling

- With these honing apparatus, even untrained persons can achieve the highest precision and surface quality immediately and without special training.

- With micrometric expansion

- 1 pitch = 0.001 / 0.002 mm expansion of the honing tool

- 1 complete revolution = 0.02 / 0.04 mm expansion

- Maximum 15 revolutions, i.e. 0.3 or 0.6 mm

- The units have an adjustable stop

- Repetition accuracy within 0.001 mm

Honing tools

- Are expanded evenly and absolutely parallel on the entire circumference (self-centring)

- Available from Ø 1.5 mm for through holes

- Available from Ø 1.5 mm for blind holes

- A micrometric expansion of the honing tools, which work according to the lapping principle, are guarantees for top performance.

Mu-Tools 1040

Hand honing apparatus type 1040 for diameters from 11 to 70 mm.

Technical data

- For honing tools Ø 11 to 70 mm

- Turns your drilling, turning or milling machine into a precision honing machine

- Very handy design and very easy handling

- With these honing tools, even untrained personnel can achieve the highest precision and surface quality without special training.

- With micrometric expansion

- 1 pitch = 0.001 / 0.002 mm expansion of the honing tool

- 1 complete revolution = 0.02 / 0.04 mm expansion

- Maximum 25 rotations, i.e. 0.5 or 1 mm

- The units have an adjustable stop

- Repetition accuracy within 0.001 mm

Honing

- Are expanded evenly and absolutely parallel on the entire circumference (self-centring)

- Available from Ø 11 mm for through holes

- Available from Ø 11 mm for blind holes

- A micrometric expansion of the honing tools, which works according to the lapping principle, guarantees top performance.

Procedure

The tool is inserted into the bore to be machined and moved by turning and oscillating (longitudinally back and forth). The cutting edges of synthetic, natural and CBN (borazon) diamonds are pressed against the bore with a pressure which can be adjusted by a micrometric drum where each division represents a 1 micron expansion in the tool diameter.

The rotational speed of the drum allows the pressure of the diamond in the material to be adjusted ‒ by hand ‒ for rapid machining or polishing. This gives the surface of the inner wall of the cylinder its characteristic appearance with grooves (usually at an acute angle) that cross each other and extend diagonally in the cylinder (also called cross grinding). This gives the cylinder defined roughness properties with high residual adhesion for engine lubricant (hydraulic oils, engine oils).